& Mechanism

Green Chem

& Mechanism

Reaction & Reagents info

- EDCI is 1-Ethyl-3-(3-dimethylaminopropyl)carbodiimide (also called EDC). Sometimes, it is also mentioned as WSC (water-soluble carbodiimide)

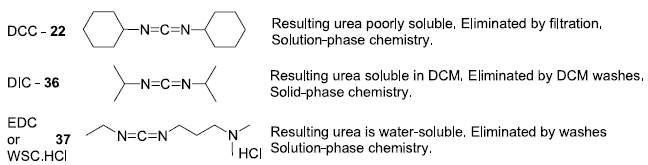

- Unlike DCC wherein the corresponding by-product viz., DUC (Dicyclohexylurea) is insoluble in water, EDCI and its urea by-product are soluble in water and hence they can be eliminated in the work-up using aqueous washings.

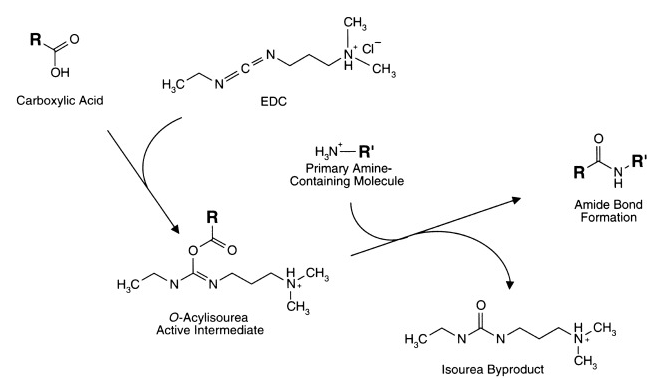

- Carbodiimide (e.g; EDCI) react carboxylic acid to form O-acylisourea, an activated intermediate. The amine reacts with O-acylurea to result in amide

Advantages:

- Urea byproduct is water-soluble and can be removed during aqueous work-up

Disadvantages:

- EDCI is expensive. This makes it less attractive in late phase development

Acid-Amine Coupling by EDCI:

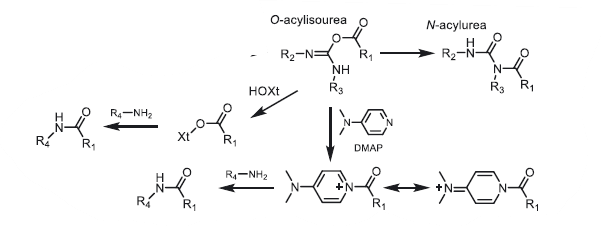

- Side-product formation: The O-acylisourea can also rearrange by intramolecular acyl transfer to give the N-acylurea, which is an irreversible pathway that does not lead to desired amide. Additives are usually used along with carbodiimides to avoid side-product formation

Commonly used carbodiimides on scale:

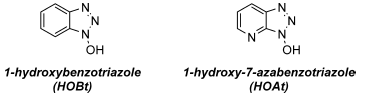

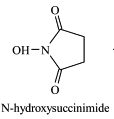

Additives or Activators:

- Additives or activators such as HOBt, HOAt, HOSu or Oxyma pure® are strongly recommended in all cases of amide bond formations with carbodiimides.

- These additives are helpful to enhance the reactivity and also to reduce formation of epimers as well as N-acylureas.

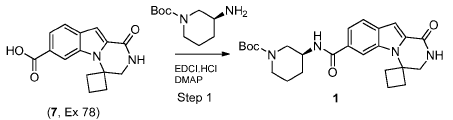

- As an alternative to the use of N-hydroxylamines (HOBt or HOAt), catalytic amount of a tertiary amine, DMAP could also be used to favor the progress of the reaction

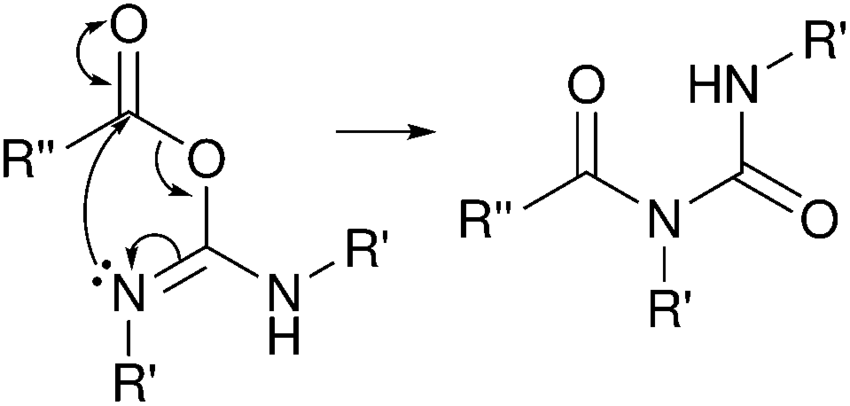

Mechanism of activation by HOBt and DMAP when used as an additive with carbodiimide:

- HOBt and HOAt have explosive character, especially in water-free form

- HOBt and HOSu are commonly used additives. HOAt is very expensive

- HOSu is completely shelf-stable. A drawback of HOSu is due to its hydroxamic acid structure susceptible to the Lossen-rearrangement. This side reaction can be observed under condensation conditions and leads to the introduction of an additional β-alanine.

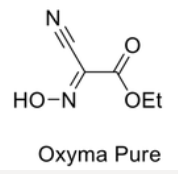

Oxyma Pure® (Ethyl 2-cyano-2-(hydroximino)acetate)

- A recently developed additive and is trademark of Luxembourg Bio Technologies Ltd, Rechovot, Israel

- Oxyma Pure®is a non-explosive alternative to HOBt or HOAt, and allows high coupling rates at low racemization when applied in combination with carbodiimides.

Mechanism

Acid-Amine coupling by EDCI – Mechanism

- Carbodiimide react carboxylic acid to form O-acylisourea, an activated intermediate. The amine reacts with O-acylurea to result in amide

Acid-Amine coupling by Carbodiimides – General Mechanism

- Alternatively, excess carboxylic acid can react with the O-acylisourea to form the symmetrical anhydride, which is also a good acylating agent. Acylation of an amine with the symmetrical anhydride also produces amide.

- Side-product formation: The O-acylisourea can also rearrange by intramolecular acyl transfer to give the N-acylurea, which is an irreversible pathway that does not lead to desired amide

Additional details

Acid-Amine Coupling by EDCI:

General Procedure-1:

To a solution of acid (1 eq.) in CH2Cl2 (10 Vol) at 0 °C, amine (1 eq.), HOBt (0.1 eq.) and DIPEA or Et3N (1.2 eq) are added. EDCI (1.2 eq.) is added to this mixture in several portions for ten minutes. The reaction is then brought to RT and stirred overnight. The reaction is monitored by TLC. The organic layer is diluted with CH2Cl2 (10 Vol) and then successively washed with water (15 ml x 2) and brine solution (15 ml). The resultant organic layer is dried using sodium sulphate, filtered and concentrated under reduced pressure. The crude product is purified by column chromatography.

Note; If acid or amine is used in excess, during work-up, the reaction mixture is washed with NaHCO3 or dil. HCl to remove excess acid or amine.

General Procedure-2:

To a solution of amine (1 eq.) and DMAP (1.2 eq) in CH2Cl2 (10 Vol) at 0 °C is added acid (1 eq.), followed by EDCI (1.2 eq.) in portions for ten minutes. The reaction is then brought to RT and stirred overnight. The reaction is monitored by TLC. The organic layer is diluted with CH2Cl2 (10 Vol) and then successively washed with 10 % citric acid (10 Vol), water (15 ml x 2), NaHCO3 solution and brine solution. The resultant organic layer is dried using sodium sulphate, filtered and concentrated under reduced pressure. The crude product is purified by column chromatography.

Note:

- EDCI is 1-Ethyl-3-(3-dimethylaminopropyl)carbodiimide. Sometimes, it is also mentioned as EDC, EDAC

- The most preferable solvent is DCM. Other solvents are DMF

- Unlike DCC (Dicyclohexylcarbodiimide) wherein the by-product (Dicyclohexylurea) is insoluble, the byproduct from EDCI namely 1-Ethyl-3-(3-dimethylaminopropyl)urea is soluble in water. Hence, the work-up becomes much easier in case of EDCI

For more details on reactions and reagents,

refer to the tab "Reaction, Reagents and Mechanism"

Typical Procedure:

- Low-epimerization Peptide Bond Formation with Oxyma Pure: Preparation of Z-L-Phg-Val-OMe (OrgSyn) — Open access

- Condensation using EDC and HOBt (TCI) — refer to sub-section “Applications & Literature” — Open access

For more details on large-scale reactions and OPRD procedures,

refer to the tab "Scale-up & Green Chem"

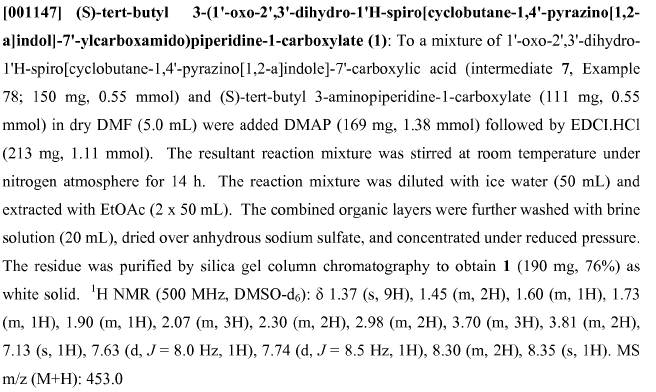

WO2010038081, page No 477

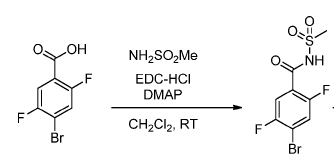

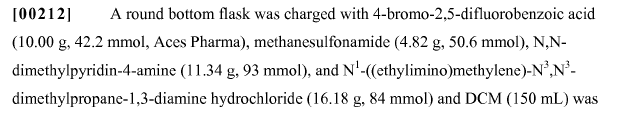

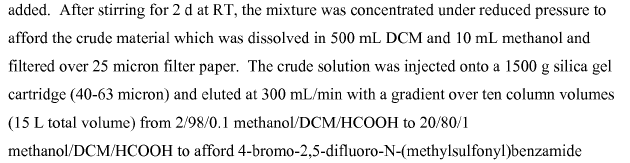

WO2014149164, page no. 456

WO2015051043, page no. 43

Green Chem

EDCI has widely been used on large-scale and there are several reports available in OPRD

Scale-Up Typical Procedure:

- Process Development and Scale-Up of a Benzoxazepine-Containing Kinase Inhibitor (OPRD, 2015) – 3.83 of EDC.HCl & 3.06 HOBt hydrate are used; 4.64 Kg batch (acid derivative)

- Development of a Bulk Enabling Route to Maraviroc (UK-427,857), a CCR-5 Receptor Antagonist (OPRD, 2020) – 28.8 of EDCI.HCl is used; 50 Kg batch (amine derivative)

- Large-Scale Applications of Amide Coupling Reagents for the Synthesis of Pharmaceuticals (OPRD, 2016) – Excellent review article, providing comprehensive information on large-scale reactions of coupling reagents