& Mechanism

Green Chem

& Mechanism

Reaction & Reagents info

- Ester hydrolysis is carried out under both basic condition and acidic condition. However, basic condition is preferred

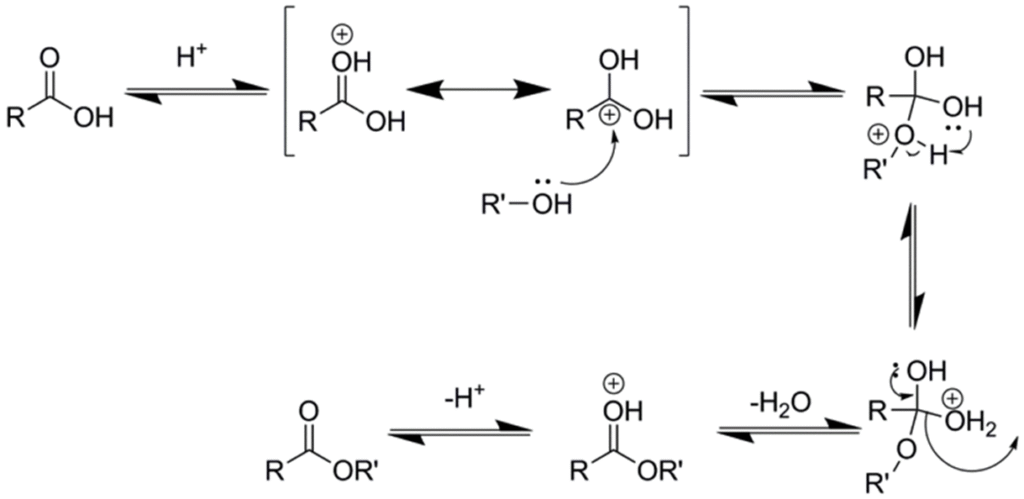

- Acidic hydrolysis of esters is reversible in nature and hence the reaction does not go to completion. It is opposite of esterification.

- Basic hydrolysis of esters is not reversible and goes to completion – more preferable method

- Basic hydrolysis results in a sodium salt of carboxylate and an alcohol. The carboxylate salt, upon neutralization during work-up, affords carboxylic acid

- Basic hydrolysis of esters is also called Saponification – soaps are prepared by the alkaline hydrolysis of fats and oils

Useful Links on Reagent & Reaction:

For review papers and other articles,

refer to the tab "References"

Mechanism

Ester Hydrolysis – Mechanism

Additional details

General Procedure-1:

To a solution of ester (1 eq.) in MeOH or EtOH or THF (10 Vol) is added aq. NaOH (2 eq. in 10 Vol) or 10% aq. NaOH (2 Vol) and stirred for 16 h The reaction is monitored by TLC. (If the reaction does not proceed, it shall be heated to 60 oC) . The reaction mixture is concentrated under reduced pressure and the residue diluted with water (10 Vol) and extracted with DCM (10 Vol x 2). The aqueous layer is cooled, acidified to pH 3 using 1 N HCl and extracted with DCM (2 x 5 Vol). The combined organic layer is then successively washed with water (10 Vol) and brine solution, dried over sodium sulphate, filtered and concentrated under reduced pressure to get the desired compound. The crude product is purified by column chromatography.

General Procedure-2:

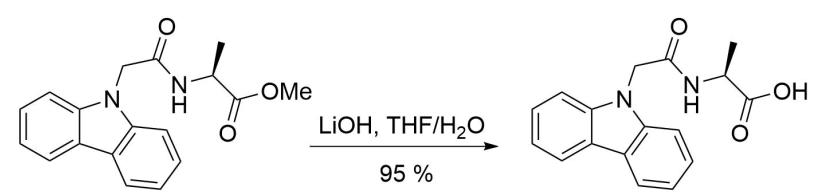

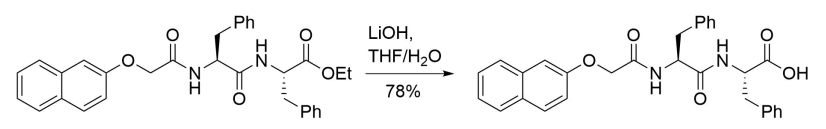

To a solution of ester (1 eq.) in THF:H2O (10 Vol; 3:1) is added LIOH (2 to 3 eq.) and stirred for 16 h The reaction is monitored by TLC. (If the reaction does not proceed, it shall be heated to 60 oC) . The reaction mixture is concentrated under reduced pressure and the residue diluted with water (10 Vol) and extracted with DCM (10 Vol x 2). The aqueous layer is cooled, acidified to pH 3 using 1 N HCl and extracted with DCM (2 x 5 Vol). The combined organic layer is then successively washed with water (10 Vol) and brine solution, dried over sodium sulphate, filtered and concentrated under reduced pressure to get the desired compound. The crude product is purified by column chromatography.

Note:

- The solvent is EtOH or MeOH or THF or THF:H2O (3:1)

- Most common bases are LiOH and NaOH

For more details on reactions and reagents,

refer to the tab "Reaction, Reagents and Mechanism"

Typical Procedure:

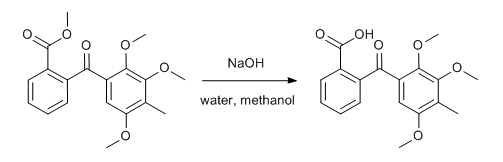

- Methyl ester hydrolysis (ChemSpider) — Open access

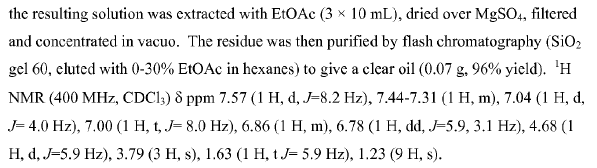

- Ester hydrolysis under basic condition-1 (ChemSpider) — Open access

- Ester Hydrolysis under basic condition-2 (ChemSpider) — Open access

For more details on large-scale reactions and OPRD procedures,

refer to the tab "Scale-up & Green Chem"

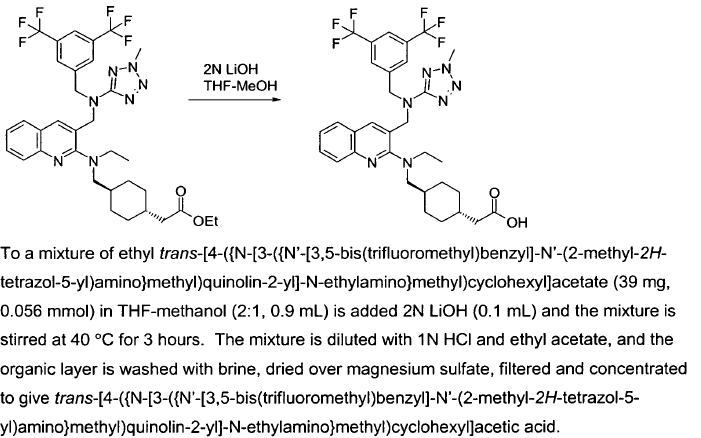

WO2007128568, page No. 50

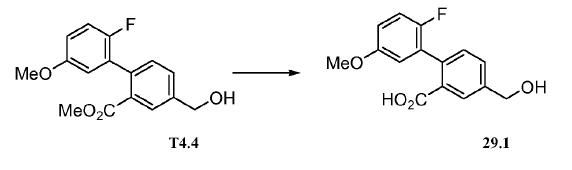

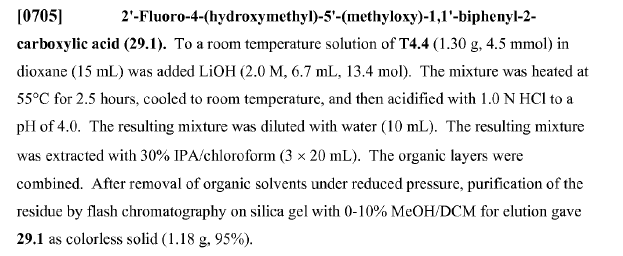

WO2010045258, page No. 303

WO2010038081, page No. 526 [General procedure – use of NaOH or Ba(OH)2]

Green Chem

Ester hydrolysis is one of the common methods that is performed on manufacturing scale.

Scale-Up Typical Procedure: