& Mechanism

Green Chem.

& Mechanism

Reaction & Reagents info

- Fischer Esterification: It involves the conversion of acid to esters under acidic conditions

- It is a reversible reaction. In order to push the reaction to the forward reaction, a large excess of alcohol is used and the by-product (water) is removed by azeotropic distillation

Advantages

- Inexpensive oxidation method on manufacturing scale

Disadvantages

- It is useful, only if alcohol is inexpensive and commercially available.

- The reaction is reversible and rate of the reaction is slow

Useful Links on Reagent & Reaction:

- Fischer Esterification (SynArchive) – Excellent compilation of reaction schemes with references

For review papers and other articles,

refer to the tab "References"

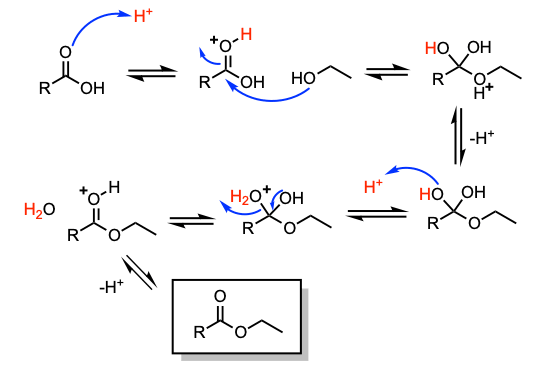

Mechanism

Fischer Esterification – Mechanism:

Additional details

General Procedure:

To a solution of carboxylic acid (1 eq.) in alcohol (10 Vol) at 0 oC is added few drops of Conc. H2SO4 (about 5 drops) and stirred at room temperature for 4 h. The reaction is monitored by TLC. If the reaction does not proceed, it shall be refluxed for 4 to 6 h. After the completion of the reaction, the reaction mixture is distilled off and diluted with DCM or EtOAc. The organic layer is then successively washed with water (10 Vol x 2), and brine solution, dried over sodium sulphate, filtered and concentrated under reduced pressure. The crude product is purified by column chromatography

Note:

- This reaction is very useful, if alcohol is inexpensive and commercially available. Methyl and Ethyl esters could be prepared easily by this method

- In place of Conc. H2SO4, PTSA could also be used

- This reaction is in equilibrium, though is more favoured. Water (i.e. moisture) tends to hydrolyze the ester back to acid. In order to drive it to the forward reaction, high-temperature reflux, Dean-Stark apparatus and molecular sieves are usually used

For more details on reactions and reagents,

refer to the tab "Reaction, Reagents and Mechanism"

Typical Procedure:

For more details on large-scale reactions and OPRD procedures,

refer to the tab "Scale-up & Green Chem"

Patent references

Green Chem.

- Fischer esterification is very useful, if alcohol is inexpensive and commercially available. Methyl and Ethyl esters could be prepared easily by this method on manufacturing scale.

- In place of Conc. H2SO4, PTSA could also be used

Scale-Up Typical Procedure: