Reaction & Reagents info

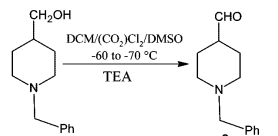

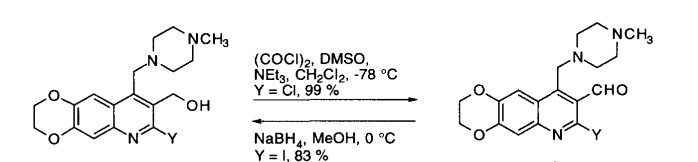

- Swern Oxidation (DMSO, Oxalyl chloride) is a mild oxidizing system that converts primary alcohol to aldehyde and secondary alcohol to ketone

- It is one of the series of oxidations involving DMSO (refer to DMSO-activated oxidations)

Advantages

- Inexpensive oxidation method on manufacturing scale

- Also, it is less toxic, compared to chromium-based alternatives (PCC and PDC)

Disadvantages

- The liberation of gases viz., malodrous dimethylsulphide (Me2S) and poisonous carbon monoxide (CO) are to be handled appropriately

- It is important to maintain the reaction mixture at -78 oC. If the temperature is not maintained, there is a possibility of formation of mixed thioacetals (see mechanism)

Useful Links on Reagent & Reaction:

- DMSO –Oxalyl Chloride (Swern Oxidation) (Reagent Guide, ACS Green Chemistry Institute) – Green Chemistry info.

- Swern oxidation (SynArchive) – Excellent compilation of reaction schemes with references

Mechanism

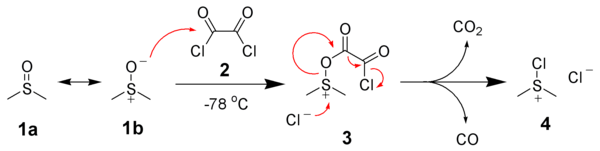

General Oxidation Mechanism

DMSO, as such, is not a good oxidising agent. However, it needs to be activated by an activator [such as (COCl)2 in Swern Oxidation, DCC in Moffatt oxidation] so that DMSO shall act effective oxidising agent (refer to DMSO-activated Oxidations)

Activation of DMSO by Oxalyl Chloride

Swern Oxidation

Formation of side product in Swern Oxidation

In Swern oxidation employing (COCl)2, one mole each of CO, CO2 and Me2S (all gaseous products) are released. HCl gets converted to NEt3.HCl during the reaction

It is important to maintain the reaction mixture at -78 oC. If the temperature is not maintained, there is a possibility of formation of mixed thioacetals

Image from “chemistryworld.com”

Additional details

General Procedure:

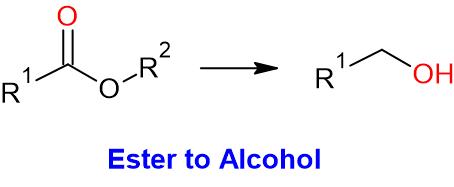

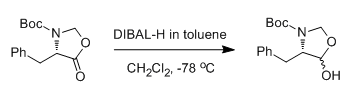

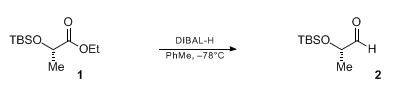

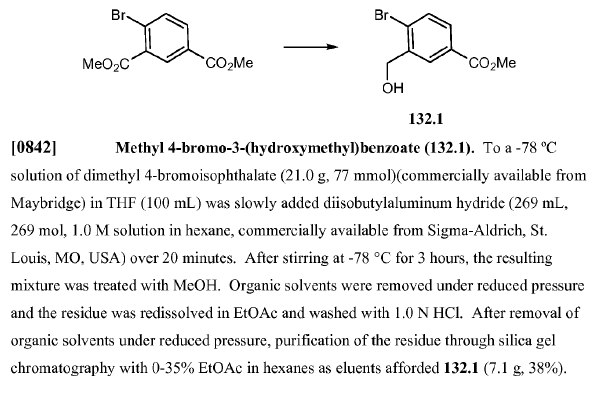

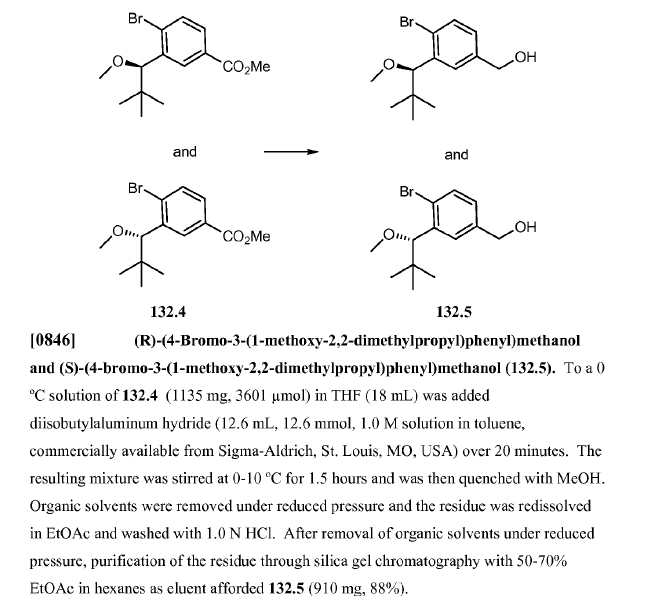

To a solution of ester (1 eq.) in DCM or THF or toluene at -78 oC is added DIBAL-H in THF or toluene (1M solution, 1 eq.) dropwise and maintained at -78 oC under nitrogen atmosphere for 2 h. It is slowly brought to room temperature and continued stirring for additional 6 h. The reaction is monitored by TLC. The reaction is quenched by adding methanol slowly, followed by addition of aqueous Rochelle’s salt solution. The resultant suspension is filtered through celite and washed with ethyl acetate/DCM. The layers are separated. The organic layer is then successively washed with water (10 Vol x 2) and brine solution, dried over sodium sulphate, filtered and concentrated under reduced pressure to get the desired compound. The crude product is purified by column chromatography.

DIBAL shall be quenched by several other methods (Quenching methods of LAH and DIBAL are almost same)

(a) by adding water (1 Vol) , 10 % NaOH (1.5 Vol), and finally again water (3 Vol).

(b) by adding saturated aqueous Na2SO4

(c) by adding aqueous solution of Rochelle’s salt (sodium potassium tartrate, KNaC4H4O6)

- Quenching reactions: Lithium Aluminium Hydride (LibreTexts Chemistry)

- Quenching reactions: Aluminium based reagents (LibreTexts Chemistry) – LAH & DIBAL-H

Note:

- DIBAL-H reduces (a) esters to alcohols, (b) nitrile to aldehyde and (c) Lactone to Lactol

- If the reaction is maintained at -78 oC, DIBAL-H reduction of ester results in aldehyde (partial reduction). However, it is bit difficult to control DIBAL-H reduction to stop at aldehyde stage

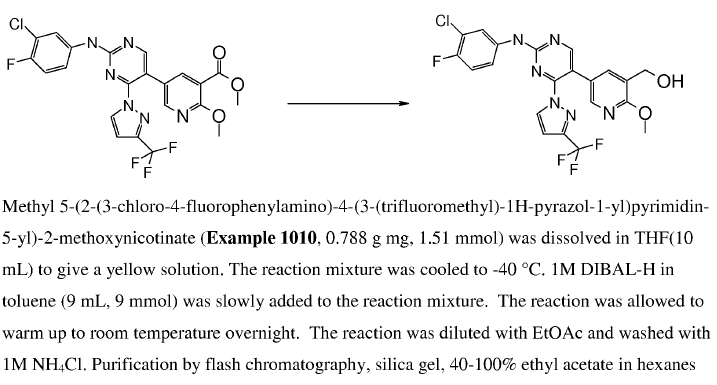

Typical Procedure:

WO2010045258, page No. 347

WO2010045258, page No. 349

WO2010038081, page No. 818

Swern oxidation could be carried out on large-scale. However, the reaction involves the liberation of 1 eq. each of the gases such as Me2S (dimethylsulphide), CO (carbon monoxide), CO2. Appropriate safety controls are to be ensured while performing manufacturing. During work-up, HCl gets converted to amine salt (such as NEt3.HCl).

- Swern Oxidation is one of the inexpensive methods to manufacture aldehydes or ketones from Alcohols

- The liberation of gases viz., malodrous dimethylsulphide (Me2S), poisonous carbon monoxide (CO) and CO2 are to be handled appropriately

- It is important to maintain the reaction mixture at -78 oC. If the temperature is not maintained, there is a possibility of formation of mixed thioacetals (see mechanism in General Info section)

Scale-Up Typical Procedure:

- An Improved and Efficient Process for the Production of Donepezil Hydrochloride (OPRD, 2008) – 4 Kg batch; 3.5 Kg of DMSO & 3.7 Kg of (COCl)2 have been used

- Convergent Catalytic Asymmetric Synthesis of Camptothecin Analog GI147211C (Tetrahedron, 1997) – 100 g batch

Green Chemistry Aspects: