& Mechanism

Green Chem

& Mechanism

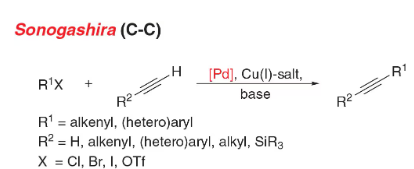

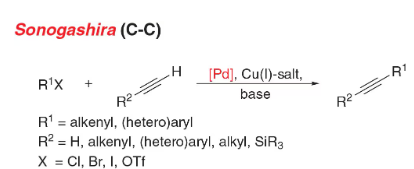

Reaction & Reagents info

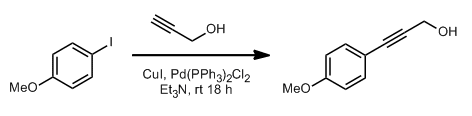

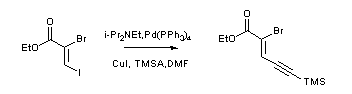

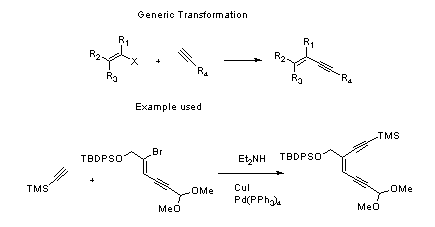

- Sonogashira coupling: C-C bond formation involving aryl or vinyl halides with terminal alkynes to generate conjugated enynes and arylalkynes.

- Reactant-1 (Nucleophile): Terminal Alkyne

- Reactant-2 (Electrophile): Organohalide

- Solvents: THF, CH3CN, EtOAc

- Catalyst: Catalytic Palladium [Pd(PPh3)4 (tetrakis), (Ph3P)2PdCl2 (dikis)] & Cu(I) salt [CuI or CuBr]

- Bases: Et3N

Useful Links on Reagent & Reaction:

- Sonogashira Coupling (SynArchive) – Excellent compilation of reaction schemes with references

Mechanism

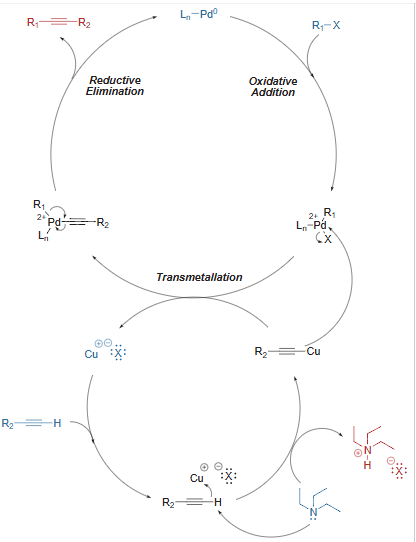

Sonogashira Coupling – General Mechanism

- The mechanism follows Oxidative addition – Reductive elimination cycle.

- Palladium and copper co-catalyzed Sonogashira coupling is reported to proceed via two independent catalytic cycles

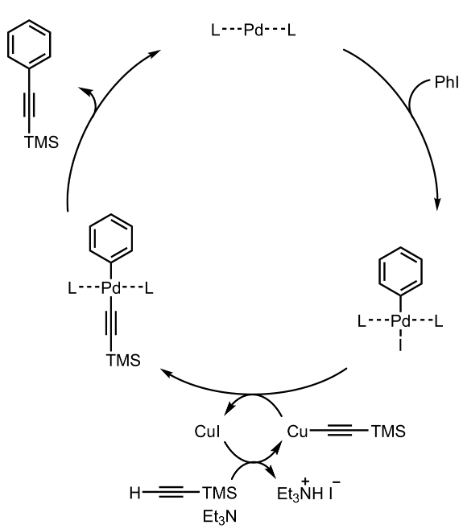

Sonogashira Coupling – Mechanism with specific example

Additional details

General Procedure:

A mixture of Bromo-aromatic ring (1 eq ), alkyne derivative (1 eq), bis(triphenyl phosphine)palladium [II]cholride (0.025eq ) and CuI (0.1eq ) were taken in freshly distilled DIPEA (10 Vol). The mixture degassed, and stirred at room tempperature overnight under nitrogen atmosphere. The reaction was quenched with aq. NH4Cl (10 Vol, 10% solution) and extracted with EtOAc. The solvent was distilled off and the resultant residue was purified by silica gel column to get the desired compound.

Note:

- This reaction is highly stereospecific and regioselective, as similar to Suzuki.

- The general trend of substrate reactivity towards oxidative addition:

vinyl iodide ≥ vinyl triflate > vinyl bromide > vinyl chloride > aryl iodide > aryl triflate ≥ aryl bromide >> aryl chloride

- The terminal alkyne substrate exhibits a relatively broad range of functional group compatibility

For more details on reactions and reagents,

refer to the tab "Reaction, Reagents and Mechanism"

Typical Procedure:

For more details on large-scale reactions and OPRD procedures,

refer to the tab "Scale-up & Green Chem"

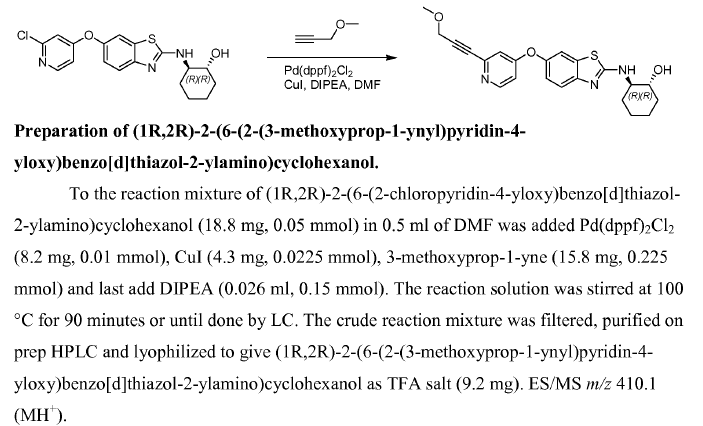

WO2007121484, page no. 174

Green Chem

Sonogashira coupling has been carried out on large-scale.

Scale-Up Typical Procedure:

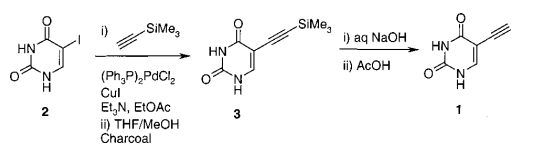

- Process Research and Development of a Dihydropyrimidine Dehydrogenase Inactivator: Large-Scale Preparation of Eniluracil Using a Sonogashira Coupling (OPRD, 2001) – 64 Kg batch (I derivative); PdCl2(PPh3)2 (0.95 Kg) and CuI (0.26 Kg) are used

Green Chemistry Aspects: